Dongguan Mingyang Ultrasonic Equipment Co., Ltd. has made significant strides in the field of industrial automation with the introduction of their new automated ultrasonic welding equipment for plastic materials. This new technology promises to streamline the assembly process and improve the overall quality of plastic products.

Established in 2014, Dongguan Mingyang Ultrasonic Equipment Co., Ltd. has been a leading manufacturer of ultrasonic equipment for several years. Their factory, located in Shipai Town, Dongguan City, Guangdong Province, has been a hub of innovation and development in the field of ultrasonic technology.

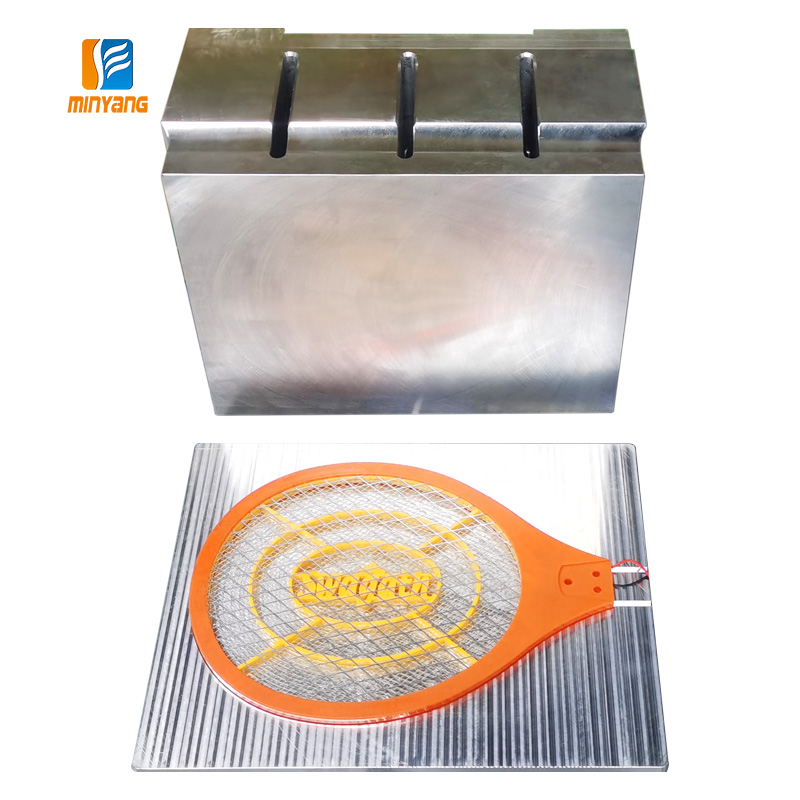

The new automated ultrasonic welding equipment is a result of years of research and development by the company's team of engineers and technicians. This cutting-edge technology is designed to meet the growing demand for efficient and high-quality assembly of plastic materials in various industries, including automotive, medical, consumer electronics, and more.

One of the key features of this automated ultrasonic welding equipment is its ability to significantly reduce the manual labor involved in the assembly process. Traditional methods of welding plastic materials often require skilled labor to operate the welding equipment, align the parts, and ensure a proper weld. With the new automated system, much of this labor is eliminated, as the equipment is capable of performing these tasks with a high degree of precision and accuracy.

In addition to reducing manual labor, the new equipment also offers improved consistency and reliability in the welding process. By automating the welding process, the equipment is able to consistently produce high-quality welds, ensuring that each product meets the required standards and specifications. This level of consistency is difficult to achieve with manual welding processes and is a major advantage for manufacturers seeking to improve the quality of their products.

Furthermore, the automated ultrasonic welding equipment is capable of handling a wide range of plastic materials, including ABS, acrylic, polycarbonate, polypropylene, and more. This versatility makes it well-suited for a variety of applications, allowing manufacturers to use the equipment for different product lines without the need for significant retooling or reconfiguration.

Another notable feature of the new equipment is its user-friendly interface, which allows for easy programming and operation. The intuitive controls and interface make it easy for operators to set up the equipment for different welding tasks, making it a valuable asset for manufacturers with diverse product lines and assembly requirements.

The introduction of this automated ultrasonic welding equipment is expected to have a significant impact on the manufacturing industry, particularly in sectors that rely heavily on plastic materials for their products. The ability to automate the welding process and improve the quality and consistency of plastic products will undoubtedly lead to cost savings, improved productivity, and ultimately, a competitive advantage for manufacturers.

In addition to the direct benefits for manufacturers, the new technology also has positive implications for the environment. By reducing the need for manual labor and improving the efficiency of the welding process, the equipment helps to minimize waste and energy consumption, leading to a more sustainable manufacturing process.

Overall, the introduction of automated ultrasonic welding equipment for plastic materials represents a major advancement in industrial automation and manufacturing technology. Dongguan Mingyang Ultrasonic Equipment Co., Ltd. has once again demonstrated their commitment to innovation and excellence, and their new equipment is poised to make a significant impact in the industry.

As manufacturers continue to seek ways to improve efficiency, quality, and sustainability, the automated ultrasonic welding equipment from Dongguan Mingyang Ultrasonic Equipment Co., Ltd. is sure to be a welcome addition to their arsenal of production tools. With its advanced capabilities and user-friendly design, the equipment is well-positioned to become a game-changer in the world of plastic material assembly.