Welding machines are the foundation of many industries, facilitating the accurate and efficient joining of two separate metals. These machines require advanced power supply schemes for welding, high-efficient power factor correction (PFC) controller, and accurate power control from the power stage. With welders relying on these machines for high power welding systems, any slowdown or malfunction can impact production and profitability. This is where an ideal welding machine system integrated circuits and reference designs come into play.

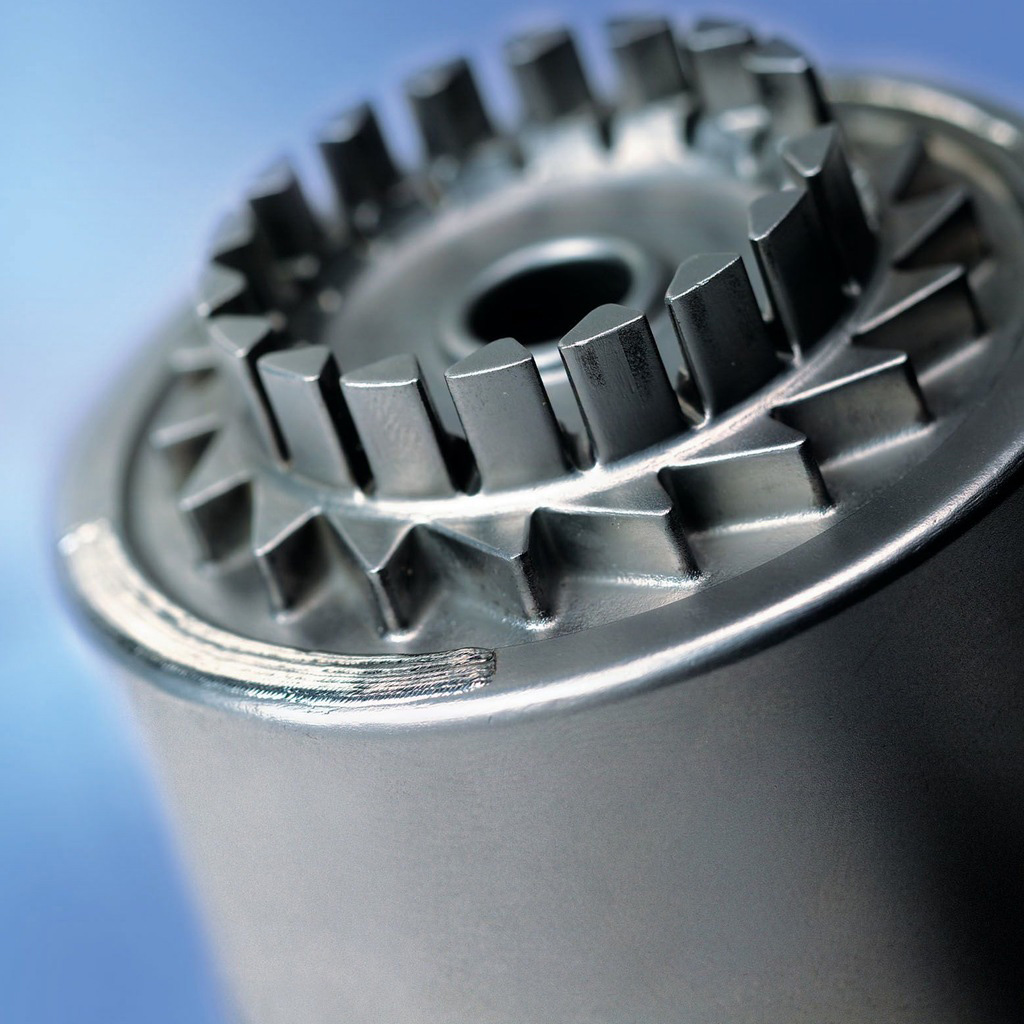

Typically, welding machines are classified into three types including ultrasonic, laser or arc welding machines. Each welding machine has a distinct power rating and usage. You can choose from a range of high power welding systems for various industries such as automotive, construction, and aeronautics that come with specific power ratings. Ultrasonic welding machines typically utilize high frequency sound waves, while laser welding machines work with high-intensity laser beams. Arc welding machines use electric arcs to join the two metals.

Advanced Power Supply Schemes for Welding

Welding machines require high power supply schemes to deal with the high currents involved in the joining process. This can be achieved using integrated circuits that provide an efficient way to manage the voltage regulation, current control, and other parameters. Such integrated circuits typically utilize a multiphase design, which is crucial for meeting the high current demand. With integrated circuits, designers can also reduce electromagnetic interference (EMI) and thermal stress on the components, ensuring operational efficiency.

High Efficient Power Factor Correction (PFC) Controller

Power factor correction (PFC) is a critical aspect of the welding machine. As the name suggests, the PFC ensures that the current drawn from the power source remains in phase with the voltage, thereby optimizing the power usage. PFC controllers utilize integrated circuits to achieve this, helping in minimizing the power loss due to waste power consumption, resulting in more efficient power usage. A high-efficient PFC controller also eliminates the need for an oversized power supply, allowing for a more compact welding machine design.

Accurate Power Control from the Power Stage

To ensure accurate power control, a welding machine system requires a robust power stage. Integrated circuits with voltage and current feedback can regulate the power output and maintain the required parameters for safe welding. These circuits also have a reverse-battery protection feature, thus preventing any accidents by shutting off the welding machine to prevent damage.

Top Integrated Circuit Designs for Improved Performance

Texas Instruments (TI) offers an extensive range of integrated circuits and reference designs that can help streamline the design of high-power welding systems. TI's integrated circuits are designed to provide top-notch efficiency, accuracy, and reliability for welding machines. Additionally, TI's products cater to both AC and DC power supply designs, and they are suitable for both use in industrial and residential welders.

TI's reference designs provide a seamless approach to designing welding machines with accurate power control, optimum PFC, and advanced power supply schemes. With TI's integrated circuits and reference designs, designers can choose from a range of options, depending on the specific requirements of their welding machine.

Conclusion

An ideal welding machine system integrated circuits and reference designs should offer accuracy, efficiency, and reliability for ultrasonic, laser or arc welding machines, regardless of the industry in which it's used. Texas Instruments' products offer precisely that, with the added benefit of top-tier innovation and compatibility. As the top-tier integrated circuit and reference designs provider for welding machines, TI's products meet the highest industry standards, ensuring the best performance possible. With TI, designers can focus on the welding machine's functionality while eliminating the worry of making several instances of the power supply, PFC controller, and power stage circuit design. Contact TI today to learn more about its integrated circuits and reference designs and get started on creating the ideal high-power welding system for your application.